Pulling Codes: The Story of Code P0446

February 20, 2011

By Carlton Banks. This is the first in a series of investigations covering many states’ top emissions-related codes. Our goal in this report is to discuss the characteristics of the P0446 code as it applies to many GM systems.

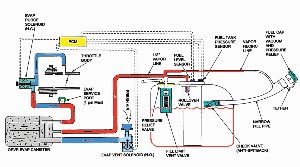

The EVAP monitor on some GM systems must complete a four-step process in order for the monitor to successfully run. The first test involves running a weak vacuum test. This checks to see that an acceptable vacuum is being generated with the purge solenoid open and the vent solenoid closed. A pass will be issued if a pre-determined target voltage is reached on the fuel tank pressure (FTP) sensor; a failure in this area will yield a code P0440 – Large Leak Detected.

The second test that is performed is a small leak test. The purge solenoid is closed during this test and a vacuum decay time is monitored and, if acceptable, a system pass will be issued. A failure in this area will yield a code P0442 – Small Leak Detected.

The third test is a path restriction test. The vent solenoid is open throughout this entire test. The purge solenoid that was previously closed will be open for a short period of time and will then be closed again. The FTP voltage should drop to zero inches of mercury. A failure in this area will yield the infamous P0446 code – Vent Path Restriction Check.

The last and final test is the purge solenoid leak test. The purge solenoid and vent solenoid will both be in the closed position while the FTP voltage is monitored for an increase in voltage. A failure in this area will yield a code P0496 – Purge Solenoid Leak Test.

It should also be mentioned that a “service bay test” may be available for the vehicle you’re working on as a means to confirm a repair and also to promote the EVAP monitor to run. The “service bay test” is normally located under “special functions” on the TECH 2 scan tool. The fuel level must between 15% and 85% and the coolant temperature must be within a certain parameter in order for this test to run successfully.

Figure 1

Now that we’ve had a quick review of how the system works, let’s begin our investigation into pulling codes. Our first case study involves a 2004 Pontiac Grand Prix. The customer complains that the fuel tank is very difficult to fill with gas; I have also noticed that there is an emissions test report from the state on the dash. The technician who is working on this vehicle has already concluded that a leak is present in the EVAP system. A smoke machine has been prepared to assist him in finding this leak.

It was interesting to note that the code description was not reviewed first as a starting point in solving this case. The code description is often referred to as the “descriptor.”

Figure 2

This is an important first step in beginning any diagnostic journey. A code P0446 has been stored in memory. Our descriptor for this code (see Figure 1) states that this DTC checks the EVAP system (Figure 2) for a restricted or blocked vent path. The scan tool being used to check this system is the GM Tech 2. We will take advantage of some of the graphing functions of the scan tool to help draw a conclusion to repair. See Figures 3-5.

Figure 3

Figure 4

Figure 5

Confirming the Code

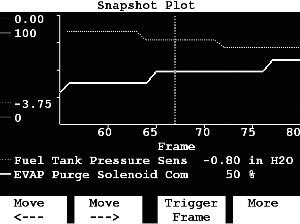

The first diagnostic step is to confirm that we have a valid code. We begin our analysis by viewing the PID for the FTP sensor; it should be between 1.3 and 1.7 volts. If the FTP voltage is incorrect, correct this first before proceeding.

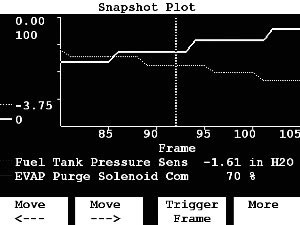

The second step is to command the purge solenoid to draw a vacuum on the EVAP system. Keep in mind that the vent solenoid is open for the entire test. If a strong vacuum is generated, we have a restriction or block in the EVAP system.

The next step is to take off the hose from the purge solenoid at the canister and then command the purge solenoid to draw a vacuum on the EVAP system again. If a vacuum is generated, the restriction is in the hose. If no vacuum is generated on the system, replace the hose and disconnect the hose from the vent solenoid at the canister. If no vacuum is generated, the vent solenoid or hose has a restriction. If a strong vacuum is generated, the canister is restricted.

After performing the test procedures on our vehicle, we found that the charcoal canister was restricted. The canister was replaced and the repair confirmed per the Tech 2 scanner. The system is now working as designed.

GM Enhanced EVAP Testing Using the Tech 2 (Functional Test)

DIRECTIONS:

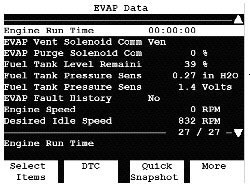

1. Turn the ignition key to the On position (do not start the engine). Allow one minute for the EVAP system to stabilize. Using your navigational skills with the Tech 2 scan tool, find the data list that shows the voltage and vacuum values for the FTP sensor.

2. You must now proceed to check the nominal voltage of the FTP sensor per the scan tool, a range of 1.3 to 1.7 volts should be noted. Note: The gas cap must not be removed. Record your observation below:

Record the nominal voltage that you noted on the Tech 2: ________ volts.

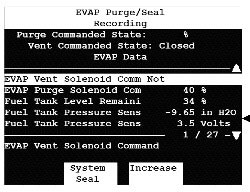

A visual of the EVAP data screen showing the nominal voltage on the FTP sensor. A range of 1.3 to 1.7 volts has been noted on known-good systems. (It is important that the gas cap not be removed during this test.)

3. You may now start the engine and proceed to the EVAP testing area of the scan tool. It is important that you first verify that the proper vacuum is available to the purge solenoid at idle. This will enable the system to be able to generate a vacuum and also perform a system seal. The suggested purge solenoid duty cycle test percentage is 30%.

4. Did this system have the ability to generate a vacuum? _______ Yes ________ No

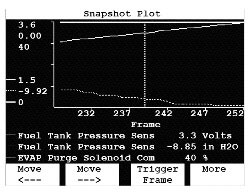

A graph showing vacuum generation was achieved using Tech 2 EVAP commands. A typical system can generate anywhere from -8” of water to -12” of water.

It is not uncommon for these systems to generate anywhere from -8 to -12” of water. Did your system generate vacuum levels within this range? ________ Yes ________ No

Note: If the system is not able to generate a vacuum, the reason may be due to a gross leak failure. If the system is able to generate a vacuum, but will not hold or maintain its vacuum levels, it may be due to a small leak failure.

5. Did this EVAP system maintain vacuum once it successfully built to an acceptable level? _______ Yes ______No

Note: Check to see if over time the system is able to maintain acceptable vacuum levels. An acceptable rule of thumb: FTP voltage should not decrease by more than 0.4 volts in 20 seconds.

This Tech 2 screen shows how vacuum is maintained in a known-good system. This system maintained its vacuum levels for more than 60 seconds. The screen above denotes a very impressive “System Seal.”

6. How long was the system able to hold its obtained vacuum levels? _________ seconds.

Based on the data you have obtained for this system, is this system working as designed or does it need further analysis?

_______ working as designed.

_______ further analysis is needed.

Once you have confirmed that a fault is present, prepare your smoke machine to find the leak.