Current Ramping – Precision Low Current Measurements for Driveability Diagnosis

September 4, 2010

Part 3: Precision Low Current Measurements for Driveability Diagnosis. Automotive technicians often use a DMM connected to a clamp-on current probe to measure current flow (amperage) in a circuit. Typical items tested are starter motor draw, blower motor draw and alternator output. The current probe clamps around a wire in the circuit under test and using voltage from its own battery (usually 2 AAA’s or a 9 volt) sends a signal to the DMM. Most current probes output 1mV for each amp detected in the circuit.

Examples:

- Alternator output of 40 amps will read 40mV on the DMM.

- Starter motor draw during cranking might read 150mV on the DMM, therefore, 150 amps are flowing in the starter motor circuit.

There are limitations to the accuracy of current probe testing when using a DMM to read the results. Those limitations are created by the DMM and the fact that a DMM will average the voltage it detects during each display update. Averaged voltage means averaged results. In example #1 because alternator output is stable from millisecond to millisecond a DMM reading of 40mV (40 amps) is useful. However, in example #2 the reading of 150mV (150 amps) is less useful because starter motor draw will change from millisecond to millisecond due to the change in load as a result of cylinder compression. Current probe measurements can be even more useful when the measurement tool is a labscope rather than a DMM.

– TECHNICIAN’S APPLICATION BRIEF –

Measuring Current Flow to Ignition Coil(s) and Fuel Injector(s) with a *Labscope [ADL7103] and **Low Amp Probe [CA30MA]

PREPARATION – “ZERO” the Probe:

- Connect the Current Probe banana leads to a DMM.

- Set the DMM to read DC Volts.

- Adjust the DMM range to read Millivolts. (Some meters will display “mV” others show “.000” or “0.000”)

- Slide the Current Probe power switch to the ON position.

- Press the “ZERO ADJUST” thumbwheel and turn it until the DMM display shows 000mV or .000 or 0.000 volts. The CA30MA sends 100mV for each amp it senses to the DMM. Each 1mV = 10 milliamps – proper zero adjustment is essential for accurate readings.

HOOKUP:

- Connect Current Probe banana leads to banana to BNC adaptor.

- Connect adaptor to CH A.

- Place Current Probe clamp around either the power or the ground wire of the circuit under test.

SCOPE SETTINGS – Ignition Coil Test for Standard Distributor Ignition System:

| VOLTS/DIV | 0.1V/div |

| TIME/DIV | 1mS/div |

| SLOPE | Rising Edge |

| Trigger Level | .3V (300mV) |

| Trigger Mode | NORMal |

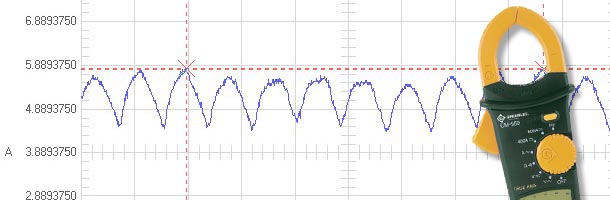

Use F5 “MOVE A” and Arrow Down Key to move the ground marker near the bottom of the screen. Then use Arrow left Key to position Trigger Position to left side of display (fig.1). Figure 1 shows the waveform of current to the ignition coil of a GM HEI system at idle. Using the voltage cursors, the peak current measures .600V (600mV) this means that 6 amps are flowing through the ignition coil. Notice that current is building up for just over 3mS and full current (6 amps) is flowing for about 2mS.

Current Flow to Ignition Coil

In figure 2 we are still examining the GM HEI ignition coil.

- Change the TIME/DIV to 20mS/div.

Current Flow to Fuel Injector(s) – TBI

SCOPE SETTINGS:

Same as single event ignition coil (fig.1) – except TIME/DIV = 0.5mS/Div.

Using the voltage cursors, the peak current measures .420V (420mV). Therefore, peak Amperage is 4.2 amps. (Each 100mV = 1 Amp in the circuit.)

Once there is sufficient current to open the injector the current limiter circuit engages reducing the current flow to only 1 amp for the duration of the fuel spray.

The current limited portion can vary from zero time during decel to many milliseconds during acceleration or cold starting.

Current Flow to Fuel Injector(s) – PFI

SCOPE SETTINGS:

Same as TBI – except VOLTS/DIV = 50mV/Div. This is necessary because PFI type injectors usually draw about 1.2 amps. The CA30MA Current Probe output of 100mV per amp will yield a waveform of just over two divisions when the labscope is set for 50mV/Div.

- All events should be at the same power level – excessive current = shorted injector.

- Below normal power level = resistance in wiring to injector or failing injector driver.

* Automotive Labscopes often have proprietary setup requirements. The number of time divisions may differ from the standard of ten divisions across the display screen.

** Other Low Amp Clamps may differ in their voltage output per Amp. When necessary, make changes in your scope setup to accommodate the Amp Clamp being used.

To read more about Analyzing Amperage Results when testing Ignition Coils with a Low Amp Probe, click here!