INTERACTIVE LIVE CLASSROOM TRAINING

Advanced Testing Strategies

This live classroom training course will train you and your mind on logical diagnostic procedures to follow and the tools to take you to the finish line in this course.

Technicians know how to test vehicles for client complaints, but do you do it logically or just fall back on procedures and tools you are comfortable with?

Utilizing DTC's and drivability concerns, client feedback, and technician observations, the student will be shown logical steps on vehicle diagnostics by picking the most straightforward and most logical path to car repair. True go no go testing will be discussed and used to find the quickest path to a solution. Knowing the process will get you to the best solution no matter where the problem lies.

- Understand the difference and use of pre and post O2 data

- Utilize scan tools and scan tool accessories

- Evaluate hands-on testing procedures

- Interpret case studies as a learning tool

- List the critical six main inputs acquired from the scan data

- Understand the use of a VE calculator

- Describe the importance of temp sensors

- Evaluate pre and post O2 sensor patterns

Air Brakes Training

This live classroom training course covers foundational air brake system operation and servicing. This is a classroom session. The technicians will explore components in an Air brake system.

The technicians attending will be involved with component identification , operation, diagnosis and repair of most foundation brake and trailer components. The importance of proper adjustments and service will be stressed. The session will cover basic ABS air brake function and some scan tool use.

- Understand the Operation of Air-Brake Component's

- Communicate the Operation of Each Component

- Inspect a System for Needed Service

- Knowledge of Proper Brake Adjustments

- Communicate How Auto and Manual Slack Adjusters Function

- Communicate Compressor and Governor Operating and Testing

- Relate How the Components Function

- Inspect Air Brake Systems

Air Conditioning & Heating Systems

This live classroom training will explain and all thermal-related vehicle system's fundamentals, laying out practical tips for the working tech who wants to become more experienced with heating and air conditioning systems.

HVAC is becoming more complex in today's vehicles, and this course will present both traditional and cutting-edge HVAC diagnostic procedures.

As the days of simple air conditioning and heating repairs are long gone, the savvy technician must develop new strategies for maintaining and repairing today's HVAC systems.

This course will cover conventional HVAC systems and discuss electric and hybrid electric heating and cooling systems.

- Understand the Difference Between Conventional and Electric Vehicle HVAC Systems

- Describe the Difference Between R-134a and R-1234yf Systems

- Explain Proper HVAC Testing Procedures

- Explain When a Scan Tool Can Help

- Describe Common Causes of Failures of HVAC Components

- List Common HVAC Diagnostic, Recovery, and Maintenance tTools

- Identify When to Flush and When to Replace Components

- Define an Automotive HVAC System

Brakes Training

This live classroom training course will present information on how to perform proper brake service on today's modern vehicles, as well as practical information on hydraulic, power assist, parking, and drum brake systems and associated components such as wheel bearings and brake control units.

Topics include: Hydraulic systems, fluids, lines, hoses, valves, switches, repair, power assist units, and various strategies for associated electrical systems.

This course is ideal for both the new student looking to learn about braking systems and the more advanced technician seeking diagnostic techniques and ASE A-5 test preparation assistance.

- Describe Standard Brake System Components and Operation

- Understand Hydraulic Braking Systems and Components

- Explain Master Cylinder Operation and Repair Procedures

- Recall Brake Bleeding, Flushing, and Leak Testing Procedures

- Describe Drum Brake Diagnosis and Repair Schemas

- Understand Brake Power Assist Units

- Relate Disc Brake Systems, Diagnostics and Repair

- Illustrate the Operation of Non-ABS Brake Valves and Switches

- Describe Anti-Lock Braking Systems, Diagnosis and Repair

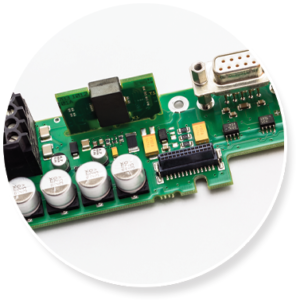

C.A.N Systems

This live classroom training course will provide a thorough understanding of the two common types of networking systems used on vehicles today, how to diagnose a multitude of networking issues, and have the ability to fully understand the networking power of today's ever-increasingly complex vehicles.

This course will cover networking high and low-speed circuits, nodes, sub-nodes, data bus circuitry, star vs. loop configurations, and vehicles using these newer systems. A heavy emphasis will be placed on scan tool diagnostics and wiring schematics interpretation to diagnose these systems.

This class uses case studies and live vehicles during the course's hands-on portion to allow the technician to perform system diagnostics. A digital meter and other various tools, including a labscope, will be used extensively throughout the course.

- Define an Automotive Networking System

- Understand How to Isolate Individual Modules for Diagnostics

- Demonstrate the Use of a Scan Tool for Networking Diagnostics

- Describe How Individual Vehicle Components All Connect to a Common Communications Network

- List the safety procedures to be followed

- Define data bus circuitry through wiring schematics

- Recall the difference between high-speed and low-speed networks

- List the advantages and disadvantages of a common communications network

Cummins Diesel

This course covers diagnostic tips and techniques for the 6.7 Cummins Diesel engines, including Dodge trucks equipped with DPF and SCR systems.

- Demonstrate Low Pressure Fuel Testing

- Demonstrate High Pressure Common Rail Testing

- EGR System Diagnostics

- Learn How to Use DPF Systems

- Diagnostics of SCR Systems

- How to Use a NOx Sensor

- Scan Data Diagnostics

Diesel Fuel System

This live classroom training course covers the many aspects of Diesel fuel testing includes some system operation and servicing.

This a hands-on workshop. The technicians will perform actual fuel testing during the session. Due to the hands-on experience in this program please consult your AVI representative for classroom sizing and requirements.

- Demonstrate Diesel Specific Gravity Testing

- Relate How to Solve Asphlatene Concerns

- Demonstrate How to Perform a Proper Fuel Volume Check

- Understand How to Diagnose and Repair Common Rail Fuel Concerns

- Communicate Other Fuel Issues

- Relate How to Do a Complete Diesel Fuel Test

- Demonstrate How to Perform a Proper Fuel Pressure Check

- Communicate How Fuel Components Work with Each Other

Diesel Training

This live classroom training course covers training that is full of information on Ford Power Stroke diagnostics covering extensive 6.7 Power Stroke repair information.

This course will demo actual testing and practical service demonstrations along with helpful tips and tricks.

Topics include: fuel testing, pressure testing, volume testing, scan tool diagnostics, diagnostic tips, turbochargers, data network diagnostics, no start diagnostics, SCR & DPF systems and much more. The instructor will also furnish the participants with detailed handouts and recommend other materials for additional participant self-study.

If you service Power Stroke Diesel vehicles, this program is a must!

- Discuss Fuel System Updates and Common Issues

- Analyze Common Rail Information and Care

- Investigate Fuel Contamination and Fuel Injection Pump Diagnosis

- Outline Turbocharger Testing, Including Boost vs. Backpressure

- Diagnose Engine Oil Issues and Evaluate Causes for Aeration

- Relate Turbocharger Issues, Including Oil and Boost Issues

- Demonstrate Proficiency in Scan Tool Use, PIDS, and Data

- Relate How Vehicle Charging Systems Work

- Communicate on Cooling Systems, Primary and Secondary Service

- Illustrate Fuel Injector Operation

Domestic Drivability Diagnostics

This course will enlighten the attendee on time saving diagnostic tips and techniques when faced with having to diagnose popular diagnostic trouble codes on today's vehicles. This course also covers diagnostic steps and strategies when the technician is confronted with a driveability concern , which has not set a diagnostic trouble code. A heavy emphasis is placed on utilizing the scan tool and the labscope to their fullest potential. Get an idea what your first step should be all while sitting in the driver's seat!

- Troubleshoot Specific Popular Trouble Codes and How to Diagnose

- Labscope and Scan Tool Testing for Issues That Don’t Set Trouble Codes

- Diagnostics of Check Engine Light Diagnosis

- Understand Why a Vehicle is Running Poorly but No Check Light is Displayed

- Understand Theft System Integration

- Learn System Diagnostic Paths

- Explain Helpful Service Tools

Duramax Diesel

This course covers Duramax 6.6 diesel engines equipped with DPF and SCR systems, along with the latest L5P systems. Procedures to properly test these systems will be covered along with many common failures that will show up in your shop.

- Demonstrate Low Pressure Fuel Testing

- Demonstrate High pressure Fuel Testing

- Analyze Major Problems Caused by Add-On Devices or Pumps

- Diagnostics of DPF Systems

- Analyzing SCR Systems

- NOx Sensor Diagnostics

- HC Injectors

- Learn Scan Data Diagnostics

Electrical Training

This live classroom training course covers the practical ins and outs of low and high-voltage electricity theory through lecture and examination of electric vehicle components. Your instructor will show proper testing and servicing procedures involved with traditional 12 volt systems and the newer high voltage components found in electric vehicles.

High voltage components covered in this course include the HV battery pack, inverter assembly, converter assembly, electric air conditioning compressor, and Motor generators 1 and 2. A heavy emphasis will be placed on safety as well as real-world diagnostic testing and repair procedures.

This course is ideal for both the new student looking to learn about basic electrical theory and the more advanced technician seeking knowledge on high-voltage systems in modern electric vehicles.

- Communicate How a Battery Works

- Define Electrical Terminology

- Illustrate Ohms Law

- Generalize How Fuses Operate

- Contrast Series and Parallel Circuits

- Illustrate the Operation of Multimeters

- Recall Basic Electrical Components

- Communicate on How to Test Electrical Circuits

- Relate How Vehicle Charging Systems Work

- Explain Alternating Current (AC) Vs. Direct Current (DC)

- Underline the Tools for Working with Electricity (DC)

Gasoline Direct Injection

Gasoline direct injection is one of the best engineering changes to extend the life of the ICE engine. Along with this new technology comes service opportunities. This session will address GDI issues along with system types and diagnostics. Master your GDI diagnostic and service skills and make more money!

- Learn GDI System Types

- Understand Low Pressure Fuel Systems

- Understand High Pressure Fuel Systems

- Demonstrate Specific GDI Diagnostic Procedures

- Carbon Buildup Issues

- No Start Diagnostics

- Common Failures

- Scan Tool Diagnostics

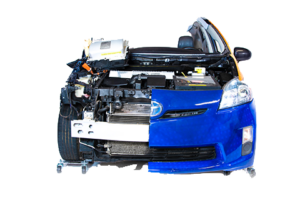

Hybrid Level 2

This live classroom training course covers diagnostic and repair techniques for automotive technicians working with high-voltage vehicles.

The course covers the components that make these vehicles unique and delves deep into their operation, their specialized components and effective diagnostic procedures. It also extensively covers the most critical subject of the lessons: safety. This class explains the vehicle’s workings, preparing the vehicle for safe diagnostic interaction, proper personal protective equipment for the technician, and recommended tools.

Topics include: Electricity fundamentals and testing procedures, wiring schematics, hybrid/EV configurations and components, safety, regenerative braking, EV cooling systems, scan tool diagnostics and much more.

- Critical Thinking that Leads to the Proper Diagnostic Path

- Inverter/Converter Components and Their Functions

- How to Test Inverter/Converter Components

- High Voltage Battery Pack Components and Their Functions

- How to Test High Voltage Battery Pack Components

- Communicate on High Voltage Battery Technology and Components

- Motor Generator Testing Using Labscopes

- Important Scan Tool PIDs & DTC Diagnostics

Hybrid Training

This live classroom training course covers diagnostic and repair techniques for working with high-voltage vehicles.

The course covers the components that make these vehicles unique and delves deep into their operation, their specialized components and effective diagnostic procedures. It also extensively covers the most critical subject of the lessons: safety. This class explains the vehicle’s workings, preparing the vehicle for safe diagnostic interaction, proper personal protective equipment for the technician, and recommended tools.

Topics include: Electricity fundamentals and testing procedures, wiring schematics, hybrid/EV configurations and components, safety, regenerative braking, EV cooling systems, scan tool diagnostics and much more.

- Understand the Fundamental Theories of Electricity and Electrical Current

- Communicate on How to Test Electric Circuits

- Generalize the Different Types of Electric and Hybrid Electric Vehicles

- Understand Personal Protective Equipment and the Procedures to Follow

- Describe Electric Vehicle Diagnostic Procedures

- Communicate on High Voltage Battery Technology and Components

- Describe High Voltage Component Testing, Removal, and Replacement

- Illustrate Hybrid and Electric Vehicle Maintenance Procedure

Intermediate to Advanced Labscope

This live classroom training course will explain how Labscopes may be the most misunderstood tool in the technician's diagnostic arsenal.

This course will attempt to break through that barrier by not only explaining the essential operation of scopes but progress through hands-on activities to advance tips and techniques for utilizing your labscope in your daily diagnostic work.

The instructor will discuss the different types of labscopes, procedures to set them up correctly, and folow the necessary activities to self-educate on their use.

Students will learn about thhe five primary signal types, set the labscope time, voltage and trigger, pattern of the signal, and the five critical dimensions of amplitude.

- Understand the Importance of Practicing with Your Labscope

- List the Different Labscope Accessories and Their Use

- Explain Labscope Triggers

- Understand Measurements Vs. Time

- Describe the Difference Between an Analog and Digital Labscope

- Demonstrate Knowledge of Common Labscope Terminology

- Secure Knowledge on Signals

- Describe Single and Multiple Traces

Low Voltage Electrical

This course will provide you with the necessary skills to diagnose electrical problems. Gain knowledge and learn the techniques critical to any electrical issue.

- Understand Meter Usage Tips & Diagnostic Approaches

- Learn How to Choose the Right Testing Tool

- Demonstrate Advanced Voltage Drop Testing

- Understand Proper Wire & Connector Repair

- Amp Testing Series & Inductive

- Wiring Diagram Tips

- Understanding Floating Grounds

- Knowledge of Isolation Testing

Pressure Transducer Testing

This live classroom training course will present to the student lecture and practical exercises on pressure transducers to determine engine mechanical, fuel system, and misfire concerns.

This relatively new form of automotive diagnostic testing uses amplified and non-amplified pressure transducers to determine specific cylinder misfires, engine blow-by percentage, restrictions in fuel injectors, valve timing, concerns, and other volumetric efficiency issues.

Valvetrain, head gasket, and cracked head issues can all be diagnosed using a pressure transducer and a labscope. this class includes a large amount of hands-on shop time working on vehicles.

- Understand What a Pressure Transducer Is and How It Works

- List the Different Types of Pressure Transducers

- Using Waveforms to Diagnose Vehicle Issues

- List the Safety Procedures to be Followed When Performing Pressure Transducer Testing

- Illustrate different locations that a pressure transducer can be placed

- Recall proper labscope waveform interpretation

- Describe how to set up for pressure transducer testing

- Understand the different diagnostic scenarios applicable to pressure transducer testing

Push Button Start Systems

Who wants to turn a key anyway? But what happens when your customer pushes the button and nothing happens. Is it the switch, Proximity sensing, Theft system, Bus or something else? This session will help answer those questions by covering the right diagnostic approaches to ensure a quick and proper repair.

- Understand Push Button Start Operation

- Learn How the Button Communicates with Sub-systems

- Describe Proximity Systems

- Data Bus Integration

- Theft System Integration

- Understand System Diagnostic Paths

- Discuss Helpful Service Tools

Silver Bullets

A “Silver Bullet” is a good starting point to a common problem or pattern designed to help solve diagnostic issues quickly. Silver Bullets are not a replacement for understanding or diagnostics, but rather a quick area to check to potentially save time and money. Since these are pattern failures, the likelihood is very high that the suggested repair will fix the vehicle.

- Chevy/GMC Trucks & Vans No Start

- No Wiper Operation & Other Complaints on GM Trucks

- RR ABS Wheel Speed Sensor Code Chevy/GMC Trucks & Vans

- Duramax P0299

- Chevy Cruise Inoperative Radio & Other Electrical Issues

- Ford Escape Misfire Codes

Testimonials

Instructor was very clear, very knowledgeable. As a shop that's trying to keep up with the newer cars, the things that are coming in, the things we need to get used to, we’re leaving this class with more confidence. Mark Eitel - K&M Automotive