Diagnostic Solutions: Ignition Coil Diagnostics

July 25, 2012

By Gary Goms. During the past century, ignition coil configurations have evolved from oil-filled canister to epoxy-filled to e-core to waste spark and to the most modern coil-on-plug or “pencil” coils. Whatever the configuration, an ignition coil creates a spark by transforming amperage into volts.

Photo 1: Most technicians are familiar with oil-filled (center), epoxy-filled (left), e-core, waste-spark and pencil-type (right) ignition coils.

Whatever the configuration, an ignition coil has three parts: a primary circuit, a secondary circuit and a soft-iron core. A magnetic field is created around the soft-iron core when an electric current flows through the primary circuit or winding. When the current flowing through a few hundreds of turns of primary winding is interrupted, the resulting magnetic field collapses into many thousands of turns in the secondary winding. By “cutting” the magnetic field many thousands of times, the secondary winding multiplies or transforms low battery voltage into the voltages needed to create an ignition spark.

Keep in mind that the actual output voltage of the coil depends upon the air/fuel (A/F) ratio and the running compression of the engine at the spark plug gap. In general, lean A/F ratios and high cylinder pressures tend to increase the voltage requirement at the spark plug.

THE PRIMARY CIRCUIT

An ignition coil primary circuit includes the battery voltage or B+ terminal attached to a 12-volt current source and a ground or B- terminal attached to a power transistor that controls primary current flow. To create a spark, the power transistor is commanded by the Powertrain Control Module (PCM) to form a magnetic field in the coil by grounding the primary circuit. Coil “saturation” occurs as the magnetic field is formed. The PCM then commands the power transistor to interrupt the primary circuit and collapse the magnetic field, which then creates an ignition spark.

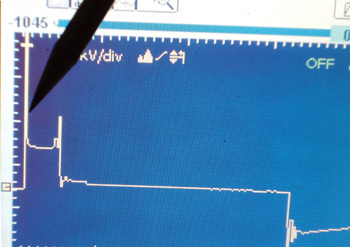

Photo 2: The coil driver saturates the primary circuit by pulling the circuit to ground.

While some import electronic ignitions mount a power transistor directly onto the coil, the power transistor in most ignitions is incorporated into a separate ignition control module (ICM). To further simplify ignition hardware, most modern configurations incorporate the power transistor or primary ignition “driver” into the PCM.

Because most modern ignition systems are capable of producing secondary voltages up to 60,000 volts or 60 kV, the ignition systems are programmed to reduce coil operating temperatures by reducing the duty cycle or “on-time” at idle speeds, and also by increasing the duty cycle at high engine speeds. This feature increases coil life by reducing the coil’s internal operating temperature.

SECONDARY CIRCUIT

Photo 3: When the coil driver interrupts the primary circuit, the coil’s magnetic field collapses, producing a high-voltage spark.

Toyota, among others, often utilizes a “hybrid” waste-spark ignition on V-block engines. In this configuration, the ignition coils on one cylinder bank are mounted directly onto the spark plugs, and the spark plugs on the opposing bank are connected to the coils by ignition cables. In contrast, a dedicated COP ignition system mounts the coil directly onto the spark plug. Obviously, the COP system has the least number of components to fail. See Photo 3.

IGNITION COIL DIAGNOSTICS

Right off the top, I want to emphasize that intermittent ignition coil failures are tough to diagnose because ignition coil windings tend to be very sensitive to engine heat. Remember that heat increases primary and secondary circuit resistance and that both windings expand with heat. This is why an ignition coil might pass all shop tests, but will still fail when subjected to high operating temperatures and maximum loads.

I’m also the first to say that a variety of opinions exist about how to test ignition coils and ignition systems. The most basic method is measuring a coil’s primary and secondary resistance. If a coil doesn’t meet the manufacturer’s specifications, it should be considered defective. But meeting primary and secondary resistance specifications on the bench is no guarantee that the coil will perform correctly under extreme heat and load.

The next method is a process of elimination that tests the coil driver. Because cranking dwell time on modern systems can be seven degrees or less, never use a conventional test light for testing. Instead, use a DVOM to measure duty cycle or to measure for the presence of voltage drop at the coil B- as the driver switches the coil on to off. If the coil driver works, the coil is presumably defective.

The most conventional method for testing coils is to observe how well the spark jumps across an air gap while cranking the engine. This method has several problems because cranking the engine with a defective or poorly charged battery simply won’t deliver the primary voltage needed to properly saturate the coil’s primary windings. The battery must also maintain at least 10 volts at the PCM to keep the PCM fully operational.

Because the testing at an air gap must be constant and measurable, many techs use spark testers that create approximately a 0.250” gap for older ignitions and a 0.500” spark gap for later, high-voltage ignitions. The color of the spark often has more to do with atmospheric contamination than it does with the quality of the spark. In some cases, a really “hot” spark is nearly invisible to the eye. Last, any spark generally appears weak when seen in direct sunlight, which can confuse the diagnosis.

Ignition scope analysis can be equally confusing because, during the days of contact point ignitions, technicians compared their scope captures with an “ideal” waveform pattern that contained a specific number of primary and secondary oscillations in the coil waveform. But, when transistors are used to interrupt the primary circuit, the primary and secondary waveforms can vary dramatically from the “ideal” waveforms pictured in many automotive texts.

As the epoxy-filled and external iron core configurations (e-core) were popularly introduced in the early 1980s, we saw the primary and secondary waveform oscillations nearly disappear. With a waste-spark secondary ignition coil operating on both positive and negative grounds, we also see quite a difference between compression and exhaust waveforms. Because most COP designs lack accessibility, secondary waveform analysis has become difficult to execute in most applications.

The type of scope equipment being used is also critical for an accurate waveform analysis. Most automotive lab scopes won’t tolerate the high voltage “kick” encountered during primary and secondary circuit testing. Others lack the resolution or definition needed for accurate coil waveform analysis. On the other hand, most will display a secondary waveform by using an inductive adapter attached to the spark plug cable or to the coil top on COP applications.

Photo 4: This “flat-top” waveform indicates that this coil is current-limited at about six amperes.

CURRENT RAMPING

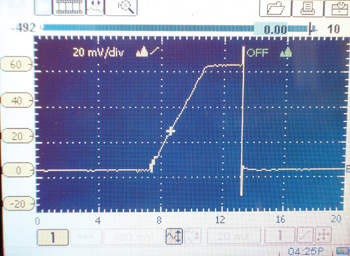

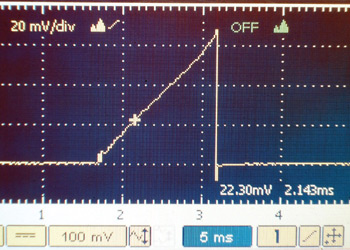

Because access to secondary waveform testing is nearly impossible on modern COP ignitions, most advanced diagnostic technicians use a lab scope and a low-amperage inductive current probe to measure and display current flow through the coil’s primary circuit. See Photo 4.

Photo 5: This current ramp represents current flow through a coil-on-plug configuration. Notice that the current is about 4.4 amperes and is non-limited.

Access to the primary circuit can most often be obtained through the “ignition” fuse in the vehicle fuse box or directly at the primary ignition wiring harness leading to the ignition coils. In many cases, all of the system’s ignition coils are powered by a single wire, which simplifies attaching an inductive current probe.

Photo 6: Access for an inductive probe can be attained on some COP ignitions by installing jumper wires between the coil connector and coil.

If the coil driver in the PCM is ruined or if an ICM fails, it’s always good procedure to check the current ramp on the ignition coil. Remember that most ignition coils shouldn’t draw more than eight amperes. If in doubt, compare amperage draw with a similar known-good system. If a coil is drawing excessive amperage, the primary circuit might be shorted which, in turn, might ruin the new PCM or ICM. If you’re in doubt about the integrity of any ignition coil, it’s better to replace with new than to risk a costly comeback.