Diagnosing Murphy’s Law Under the Hood of a Ford F-150

August 8, 2012

Oops! We could not locate your form.

By Gary Goms. Most of us working in the automotive service trades are very familiar with Murphy’s Law and how it affects our shop’s cost of doing business.

Murphy’s Law says, “Everything that can go wrong usually will go wrong.”

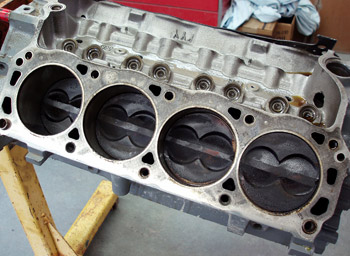

Photo 1: The even coating of carbon over the piston head indicates that the piston rings have seated.

When Murphy’s Law takes affect, a single defective part can cost us our day’s profit. A series of defective parts can cost us our week’s profit, especially on a large job like an engine replacement. If our long-term parts warranty times exceed, let’s say, 5% of our total shop revenues, we find ourselves headed toward bankruptcy.

This month’s Diagnostic Dilemma is about diagnosing a mysterious engine noise in a 1989 Ford F-150 pickup equipped with the venerable 5.0L or 302 cubic-inch V8 engine.

It’s not often that I’m called upon to diagnose internal engine problems and, in this case, I wasn’t called as much as I volunteered. I taught heavy-duty line mechanics during the early 1970s and worked heavy line during my time as a dealership auto mechanic. When I opened my shop in 1977, I did internal engine repairs for over 10 years. So diagnosing odd engine noises is a process that I’ve generally mastered on most applications.

Engine Number One

Several years ago, the engine in the F-150 was removed at approximately 130,000 miles to address cold-engine piston slap and minor oil consumption. Like many caught up in the current economy, the owner felt that his money was better spent on an engine rebuild than on payment books and hefty registration fees.

Photo 2: Scoring on the thrust side of cylinder walls 1 and 4 was very apparent on the first two engines.

Immediately after the newly rebuilt engine was started, it developed a half engine-speed tapping noise. I wasn’t present, but the installer faithfully followed the rebuilder’s instructions by installing a zinc-based oil supplement and keeping the engine above 2,000 rpm for at least 30 minutes to help the new flat-tappet camshaft and lifters break in correctly.

The installer rightfully assumed that one new lifter had some debris stuck in the lifter check valve and that the noise might go away when the debris eventually dislodged itself. As Murphy’s Law might dictate, the noise didn’t go away and, in fact, became worse. A few weeks later, my opinion was asked.

Sure enough, when the engine was accelerated over 1,000 rpm, a somewhat irregular half-speed tapping noise emanated from the passenger-side valve cover. Because the upper intake manifold plenum must be removed to access the right-hand valve cover, we couldn’t physically inspect the valve train.

Working in good faith, the rebuilder agreed to replace the valve lifters, since that was the most likely cause of the noise. The valve guides, springs, rocker arms and pushrods were also inspected when the lifters were replaced.

As Murphy’s Law would have it, the noise remained in both frequency and intensity.

Several thousand miles later, the intensity of the noise worsened. Because the right-hand valve cover couldn’t be removed without disabling the engine, I used my old Snap-on model 1665 ignition scope to disable individual cylinders. I immediately discovered an open-circuit spark plug wire on the #3 cylinder, which was then replaced. By using the non-intrusive cylinder cancellation feature, I hoped to eliminate or change the intensity of the half-speed engine noise. Here again, the noise persisted despite canceling individual cylinders.

At this point, I’m speculating that one of the valve seat inserts had come loose or that the engine had developed a valve guide problem. While a compression test revealed normal cranking pressure, a cylinder leak test indicated about 10% on six cylinders. Number 1 cylinder on the right bank came in at 15% and #4 cylinder came in at 20%.

While leakage on cylinder numbers 1 and 4 were higher than they should be for a rebuilt engine, a high of 20% certainly wouldn’t normally be indicative of the damage caused by a loose valve seat insert after 3,000-plus miles of operation.

The next step was to analyze intake manifold vacuum by attaching a pressure transducer to my lab scope. Here again, I didn’t discover any definitive issues other than a very slight anomaly in the vacuum waveform pattern on #4 cylinder.

Photo 3: Comebacks on engines are expensive. Three successive comebacks can be disastrous.

All in all, the engine ran perfectly, except for the annoying half-speed tapping noise. Looking into the right-hand cylinders with a borescope indicated that the piston rings had just seated and that no foreign materials were imbedded in the pistons.

See Photo 1.

At this point, I had exhausted my bag of tricks for externally diagnosing the cause of the mysterious half-speed tapping noise.

Failure Probabilities

Nearly any diagnosis involves the probable failure rates of various parts. For example, it’s highly unlikely that two sets of valve lifters would create an erratic half-speed engine noise at 1,500 rpm.

Not that I haven’t seen a half-speed tapping noise be caused by a spun connecting rod bearing or a severely worn valve guide, but it was highly unlikely on a freshly rebuilt engine. So the decision was made to remove the engine and send it back to our local rebuilder.

Fortunately, I visited our rebuilder just as he discovered that the new pistons on #1 and #4 cylinders were badly scored on the thrust skirt, with the non-thrust skirt appearing nearly normal. This wear pattern indicated that the piston had adequate skirt-to-wall oil clearance. This wear pattern also might indicate that insufficient wrist pin oil clearance might be causing the wrist pins to seize, which would contribute to the scoring pattern.

See Photo 2.

As the situation developed, the rebuilder re-checked the wrist pin bore diameters on the connecting rods and actually added a few ten-thousandths of an inch in diameter to the wrist pin bores on the new pistons. This was done to eliminate the possibility of a warranty return.

Engine Number Two

In short, the second engine developed the same half-speed tapping noise within 700 miles of operation. At this time, I knew that we were experiencing the full effects of Murphy’s Law. In addition, the truck owner was becoming extremely frustrated with this sequence of events. I also knew that the engine rebuilder wouldn’t be receptive to a second warranty claim and rightly so.

Because most of the old EEC-IV Ford engine management systems didn’t have data streams, I attached a 60-pin breakout box (Never toss out those old tools!) and performed a complete pin-out test on all sensors and actuators. Everything passed muster except for a minor wiring problem with the air injection diverter solenoid on the air injection system.

At this point, the original installer removed the engine and placed it on a rotating rebuild stand.

See Photo 3.

Under my supervision, we removed the oil pan with the engine in an upright position to keep all metallic debris at the bottom of the oil pan. With the exception of two very small metallic particles, the oil pan was surprisingly clean. But when we turned the crankshaft, we discovered that #1 and #4 pistons were once again scored.

In-Depth Analysis

Photo 4: The even coat of carbon in the combustion chambers indicates that the cylinders weren’t running lean. The brown color is normal on the exhaust valves due to exhaust heat.

In accordance with Murphy’s Law, the probability of two different sets of pistons scoring on the same cylinders is nearly zero. Measuring piston skirt-to-cylinder wall clearances with a set of long feeler gauges, I found that six cylinders had 0.002” oil clearance. But #1 cylinder was worn to 0.010” clearance and #4 was worn to 0.012” clearance, all within 700 miles of operation.

As expected, the rebuilder insisted that an external factor in the ignition or fuel system was causing #1 and #5 pistons to overheat and score. But all of the fuel injectors subsequently passed a pressure-drop and flow pattern test. The spark plug colors appeared normal and further diagnosis didn’t indicate a situation that could cause both end cylinders to run lean.

See Photo 4.

At this point, I’ll mention that some 5.0L Ford engines had preignition problems caused by #7 and #8 spark plug wires being routed parallel to the other. In some cases, spark induction from one wire to the other can burn a hole through the piston on one of these cylinders. Of course, that wasn’t the case here, but it’s worth mentioning just for the record.

Piston Analysis

Like all diagnostic techs, I don’t like to be defeated on any diagnosis. Once I had the right-bank piston and connecting rods in hand, I began measuring the pistons. I noticed that the wrist pin offset was about 0.100” or nearly an eighth of an inch.

While most pistons incorporate some pin offset to reduce piston slap during cold engine operation, I thought that 0.100” was more than usual.

Next, I placed a good piston in my deep freeze so I could measure the cold diameter of the piston. I was surprised that the piston diameter shrank 0.017” at 0° F. At this temperature, the wrist pins also began to stiffen. But, when heated to 200+° F, the skirt diameter barely increased by 0.002”, which (considering the cylinder diameter expands as well) was within the 0.002” skirt-to-wall clearance machined into the cylinders. In addition, the wrist pins moved freely when the piston dome was heated to 400+° F.

See Photo 5.

Photo 5: I suspected a problem with the metallurgy of the piston because metal is actually torn from the piston skirt.

I would have needed the services of an independent engineering lab if the matter went to litigation. But that wasn’t the case, so, based on my experience and observations, I felt that the root problem was caused by faulty metallurgy in the piston. But why did cylinders #1 and #4 fail in two consecutive rebuilds? If the metallurgy was at fault, why didn’t other cylinders fail?

Basic Piston Construction

The aluminum used in modern pistons contains about 5% silicon content to harden the aluminum and make it compatible with cast-iron cylinder walls. The piston is ground slightly egg-shaped and the piston head itself is generally about 0.010” less in diameter than the skirt to allow for heat expansion. Many conventional aluminum pistons also use steel struts molded in place around the wrist pins to control piston expansion as the engine warms up.

On the other hand, many modern engines are equipped with hypereutectic pistons, which have about 15+% silicon content.

The characteristics of hypereutectic piston are:

- combustion heat travels very slowly through the metal. Consequently, less heat energy is dissipated to the oiling and cooling systems.

- Because the piston dome runs hotter, piston ring end gaps must be increased.

- The skirt-to-wall clearances can be reduced because the pistons’ skirts themselves run much cooler.

- Tight skirt-to-wall clearances promote better ring sealing by holding the piston rings squarely against the cylinder wall.

The pistons in my hand were typical “rebuilder’s pistons” made in Asia. With the exception of domestic performance manufacturers, most rebuilder’s pistons are, in fact, manufactured in Asia. These pistons had no steel inserts and were presumably hypereutectic pistons. The pistons were also coated with an anti-scuffing agent. The rebuilder said that he had used these pistons many times with no negative results.

Lubrication Theory

As mentioned above, the half-speed piston tapping noise occurred during the first warm-up on the new engine. Due to the 0.100” wrist pin offset, a major load is placed on the thrust skirt to prevent cold engine piston slap. With these facts in mind, I analyzed the 5.0L lubrication system.

As with most engines, the upper main bearing shell is grooved to allow oil to flow from the main bearing to the connecting rod bearing for one-half revolution of the crankshaft. Due to the V8 configuration, the piston skirts aren’t being oiled from the connecting rod oil as the piston approaches top dead center.

The piston skirts are instead oiled by “windage” that develops in the engine as the oil turns into a fine oil mist that circulates around the interior of the crankcase in the direction of crankshaft rotation.

Looking from the front of the engine, it’s easy to see that most of the oil windage directed at #1 and #4 pistons ends up in the oil pan, especially during cold engine operation. Number 5 and #8 cylinders on bank two receive the full force of oil windage whereas cylinders #1 and #4 don’t. The center four cylinders apparently receive plenty of windage lubrication, cold or hot. In theory, if the metallurgy or construction of the rebuilder’s pistons were defective, then it would be #1 and #4 that would fail first. Keep in mind that this is just speculation on my part.

Engine Number Three

In the short version of engine number three, we specified that the replacement pistons were to be supplied by a well-known domestic manufacturer of hypereutectic pistons. The installer also insisted on starting with another cylinder block assembly to eliminate the possibility of bad connecting rods or crankshaft oiling issues. The owner also insisted on installing a reground crankshaft kit to eliminate possible oiling issues.

The engine was installed and ran perfectly for 30 miles until it lost oil pressure. When cut apart, the oil filter was full of copper metal sheared from the main bearings.

Upon disassembly, I discovered that the main bearings had developed over 0.012” of clearance. Since the maximum spec is 0.003,” it’s easy to see why the engine lost oil pressure. Other than some slight scuffing due to lack of oil pressure, the connecting rod and camshaft bearings were perfect. Using a 30x-power magnifier, I discovered that the main bearing journals were coated with microscopic bits of copper. Despite the condition of the main bearing inserts, the crankshaft journals were dimensionally perfect.

Thanks to a TSB made available by an engine machinist who regularly posts on iATN, I discovered that a crankshaft reground and polished in the wrong sequence and rotation can ruin a new set of bearings. The TSB, which was published by a major engine bearing manufacturer, indicates that crankshafts must be ground opposite of engine rotation and polished in the direction of engine rotation.

Nodular cast iron, which is used in some 5.0L crankshafts, is particularly sensitive to regrinding and polishing techniques. Reversing this procedure raises a “micro-fuzz” on the journal surfaces that rapidly files away soft bearing material. If a high-speed crankshaft polisher is used, rotational direction is not an issue.

Last, but not least, I discovered that custom crankshaft grinders generally use the same machine for grinding and polishing. Production facilities, on the other hand, generally grind the rod journals on one machine and pass the crankshaft onto another machine to grind the main journals. The latter statement explains why the connecting rod bearings survived while the main bearings were severely worn.

Summary

While it’s simply an educated guess on my part, I believe that the pistons’ metallurgy, the relatively large wrist pin offset, and the relative lack of start-up lubrication on those cylinders combined to cause the subsequent piston failures on the #1 and #4 cylinders. The crankshaft failure was simply the application of bad parts and Murphy’s Law.

Whatever the case, I helped assemble a fourth engine using the new performance pistons from the third engine and the crankshaft from the second engine. So far, the fourth engine has done well. The financial impact of these events was devastating to all involved. I donated much of my time getting to the bottom of each problem. The final cost is incalculable to the installer, rebuilder and end user.

On a more global scale, this month’s Diagnostic Dilemma is an extreme illustration of how our cost of doing business is impacted by the distribution of substandard replacement parts. Keep in mind that there is a vast difference between the price of buying a part and the cost of using a part. The price is known whereas the cost is always an unknown. Given sufficient volume, the cost of using faulty parts can devastate the economic welfare of distributor, installer and end user alike.