INTERACTIVE

AIR CONDITIONING WORKSHOP

| SKU | LT-HVAC |

| Title | Intermediate Air Conditioning |

| Duration | 2 Day |

| Target Audience | Technician |

| Purpose | Full understanding of the operation, diagnostics, and service of vehicle A/C systems |

| Course Description | This course will cover all aspects of modern air conditioning systems using both R134 and R1234yf refrigerants. The complete refrigeration cycle will be explained, and all components involved will be discussed in detail. Service and testing techniques along with equipment usage will be covered. Proper system leak testing tools and procedures will be shown and fully discussed. |

| Hands-On Learning | Yes - AVI will provide fully operational A/C system mockups to be used in the classroom. This course will require the use of an A/C machine during class. Students will use the mockups to perform a variety of procedures such as compressor replacement, leak testing and temperature testing of the refrigerant lines for diagnostic purposes |

| Expected Outcomes | Technician should be able to properly perform A/C system service and be able to explain the operation and repair requirements of any given system. |

| SKU | LT-ADV-AC |

| Title | Advanced Air Conditioning - Hybrid and EV Systems |

| Duration | 1 Day |

| Target Audience | Technician |

| Purpose | Explain unique operational characteristics of hybrid/EV air conditioning systems |

| Course Description | This course will cover the design, operation, and testing of A/C systems on hybrid and electric vehicles. These systems can come in many forms of compressor drive from belt only, belt/electric combination to full electric in either AC or DC voltage supply. A condensed discussion of the refrigeration cycle will be included. Operation, testing, and diagnostics of these systems will be the bulk of the course time. |

| Hands-On Learning | Yes - This course will include live system testing on mockups in a classroom environment and will necessitate the use of an A/C machine |

| Expected Outcomes | Upon Completion the technician should have appropriate knowledge to perform service and repairs on hybrid and EV air conditioning systems as well as the safety requirements involved with high voltage system service. |

INTERACTIVE

BRAKES WORKSHOP

In this hands-on workshop, your instructor will present information on how to perform proper brake service on today's modern vehicles, as well as practical information on hydraulic, power assist, parking, and drum brake systems and associated components, such as wheel bearings and brake control units.

Topics include: Hydraulic systems, fluids, lines, hoses, valves, switches, repair, power assist units, and various strategies for associated electrical systems.

This course is ideal for both the new student looking to learn about braking systems and the more advanced technician seeking diagnostic techniques and ASE A-5 test preparation assistance.

8 Study Hours

- Describe Standard Brake System Components and Operation

- Understand Hydraulic Braking Systems and Components

- Explain Master Cylinder Operation and Repair Procedures

- Recall Brake Bleeding, Flushing, and Leak Testing Procedures

- Describe Drum Brake Diagnosis and Repair Schemas

- Understand Brake Power Assist Units

- Relate Disc Brake Systems, Diagnostics and Repair

- Illustrate the Operation of Non-ABS Brake Valves and Switches

- Describe Anti-Lock Braking Systems, Diagnosis and Repair

INTERACTIVE

DIESEL WORKSHOP

This hands-on workshop, consisting of a minimum of 8 hours training. It's full of information on Ford Power Stroke diagnostics, covering extensive 6.7 Power Stroke repair information.

This course will demo actual testing and practical service demonstrations along with helpful tips and tricks.

Topics include: fuel testing, pressure testing, volume testing, scan tool diagnostics, diagnostic tips, turbochargers, data network diagnostics, no start diagnostics, SCR & DPF systems and much more. The instructor will also furnish the participants with detailed handouts and recommend other materials for additional participant self-study.

If you service Power Stroke Diesel vehicles, this program is a must!

8 Study Hours

- Discuss Fuel System Updates and Common Issues

- Analyze Common Rail Information and Care

- Investigate Fuel Contamination and Fuel Injection Pump Diagnosis

- Outline Turbocharger Testing, Including Boost vs. Back Pressure

- Diagnose Engine Oil Issues and Evaluate Causes for Aeration

- Relate Turbocharger Issues, Including Oil and Boost Issues

- Demonstrate Proficiency in Scan Tool Use, PIDS, and Data

- Relate How Vehicle Charging Systems Work

- Communicate on Cooling Systems, Primary and Secondary Service

- Illustrate Fuel Injector Operation

INTERACTIVE

ELECTRIC WORKSHOP

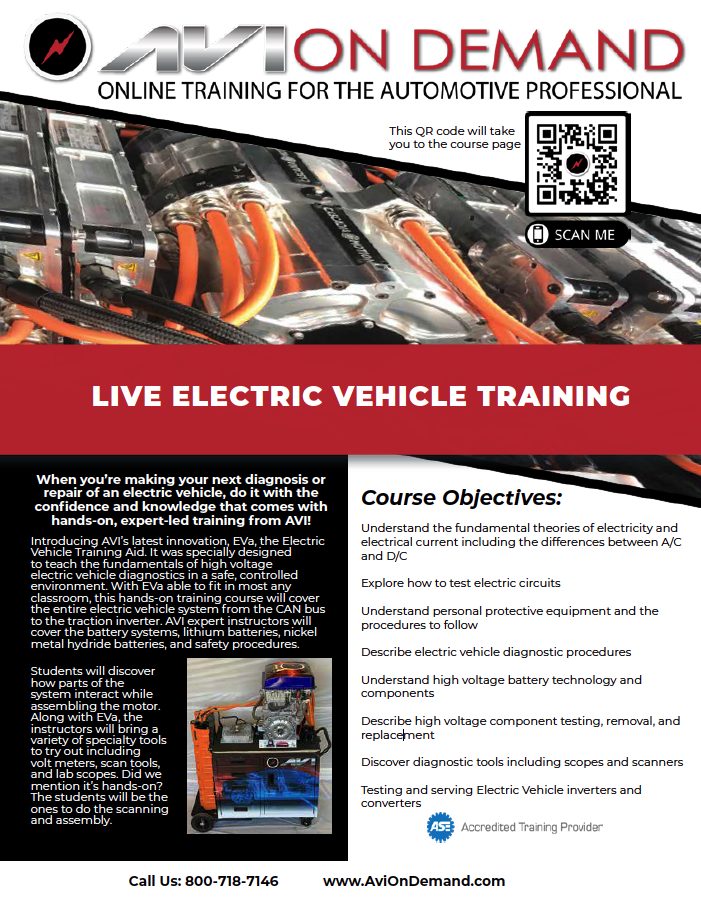

In this hands-on workshop, technicians will learn the practical ins and outs of low and high-voltage electricity theory through lecture and examination of electric vehicle components. Your instructor will show proper testing and servicing procedures involved with traditional 12 volt systems and the newer high voltage components found in electric vehicles.

High voltage components covered in this course include the HV battery pack, inverter assembly, converter assembly, electric air conditioning compressor, and Motor Generators 1 and 2. A heavy emphasis will be placed on safety as well as real-world diagnostic testing and repair procedures.

This course is ideal for both the new student looking to learn about basic electrical theory and the more advanced technician seeking knowledge on high-voltage systems in modern electric vehicles.

8 Study Hours

- Communicate How a Battery Works

- Define Electrical Terminology

- Illustrate Ohms Law

- Generalize How Fuses Operate

- Contrast Series and Parallel Circuits

- Illustrate the Operation of Multimeters

- Recall Basic Electrical Components

- Communicate on How to Test Electrical Circuits

- Relate How Vehicle Charging Systems Work

- Explain Alternating Current (AC) Vs. Direct Current (DC)

- Underline the Tools for Working with Electricity (DC)

INTERACTIVE

ELECTRIC VEHICLE WORKSHOP

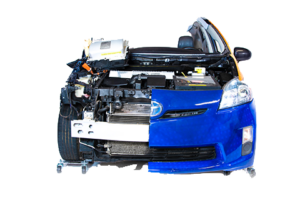

In this hands on workshop, students will learn diagnostic and repair techniques for working with high-voltage vehicles.

The course covers the components that make these vehicles unique and delves deep into their operation, their specialized components and effective diagnostic procedures. It also extensively covers the most critical subject of the lessons: safety. This class explains the vehicle’s workings, preparing the vehicle for safe diagnostic interaction, proper personal protective equipment for the technician, and recommended tools.

Topics Include: Electricity fundamentals and testing procedures, wiring schematics, electrical vehicle configurations and components, safety, regenerative braking, EV cooling systems, scan tool diagnostics and much more.

Tools Include: Volt Meters, Scan Tools, Lab Scopes, and Safety Equipment

8 Study Hours

- Understand the Fundamental Theories of Electricity and Electrical Current Including the Differences Between AC and DC

- Explore How to Test Electric Circuits

- Understand Personal Protective Equipment and the Procedures to Follow

- Describe Electric Vehicle Diagnostic Procedures

- Understand High Voltage Battery Technology and Components

- Describe High Voltage Component Testing, Removal, and Replacement

- Discover Diagnostic Tools Including Scopes and Scanners

- Testing and Servicing Electric Vehicle Inverters and Converters

When you’re making your next diagnosis or repair of an electric vehicle, do it with the confidence and knowledge that comes with hands-on, expert-led training from AVI!

INTERACTIVE

HYBRID WORKSHOP

In this hands on workshop, students will learn diagnostic and repair techniques for working with high-voltage vehicles.

The course covers the components that make these vehicles unique and delves deep into their operation, their specialized components and effective diagnostic procedures. It also extensively covers the most critical subject of the lessons: safety. This class explains the vehicle’s workings, preparing the vehicle for safe diagnostic interaction, proper personal protective equipment for the technician, and recommended tools.

Topics include: Electricity fundamentals and testing procedures, wiring schematics, hybrid/EV configurations and components, safety, regenerative braking, EV cooling systems, scan tool diagnostics and much more.

8 Study Hours

- Understand the Fundamental Theories of Electricity and Electrical Current

- Communicate on How to Test Electric Circuits

- Generalize the Different Types of Electric and Hybrid Electric Vehicles

- Understand Personal Protective Equipment and the Procedures to Follow

- Describe Electric Vehicle Diagnostic Procedures

- Communicate on High Voltage Battery Technology and Components

- Describe High Voltage Component Testing, Removal, and Replacement

- Illustrate Hybrid and Electric Vehicle Maintenance Procedures

INTERACTIVE

3 PHASE MOTORS WORKSHOP

In this hands on workshop, students will learn diagnostic and repair techniques for working with high-voltage vehicles.

his course will take a deep dive into 3 Phase Motors that are being used in today’s Hybrids and EVs. It will also cover the basics and what is different about 3 phase motors used in automotive applications versus industrial uses. Topics will include Permanent Magnet designs over the years, RPM limitations and how they are overcome, along with Induction Motors designs. We will also take a look into how and what fails in the different motor designs.

Topics include:

3 phase motors, PHEVs and EVs, diagnose and test for failures, motor designs, tools and safety procedures, bearings, brushes, and resolvers, and more.

8 Study Hours

- Understand the Fundamental Theories of Electricity and Electrical Current

- Communicate on How to Test Electric Circuits

- Generalize the Different Types of Electric and Hybrid Electric Vehicles

- Understand Personal Protective Equipment and the Procedures to Follow

INTERACTIVE

EV INVERTERS WORKSHOP

In this hands on workshop, students will learn diagnostic and repair techniques for working with high-voltage vehicles.

In this course you will learn how inverters, IGBTs, and DC-DC converters operate. You will understand how to analyze inverter voltage and amperage waveforms. Along learning how to measure the high voltage system for isolation faults, evaluate capacitors and develop diagnostic plans for DC-DC converters.

Topics include:

Inverters,IGBT,DC-DC converters, inverter voltage, amperage, waveforms, isolation faults, and more

8 Study Hours

- Describe the operation of an inverter

- Define how an IGBT functions

- Analyze inverter voltage and amperage waveforms

- Measure the high voltage system for isolation faults

- Evaluate capacitors

- Develop a diagnostic plan for DC-DC converters

- Determine the difference between buck and boost

- Perform testing on high-voltage contactors

- Evaluate capacitors

- Develop a diagnostic plan for DC-DC converters

- Determine the difference between buck and boost

- Perform testing on high-voltage contactors

INTERACTIVE

MODERN BRAKES WORKSHOP

In this hands on workshop, students will learn the latest brake advancements, including electronic braking along with hybrid and electric vehicle brake service information.

As vehicles evolve, so do their braking systems. This course covers the latest brake advancements, including electronic braking along with hybrid and electric vehicle brake service information. Several case studies are covered, including a customer complaint of a Chevy Volt steering issue during regenerative braking. Additional topics include various brake bleeding methods, stability control, ABS, brake related ADAS components and a section on the material changes made on modern brake pads and rotors.

Topics include:

brake bleeding methods, stability control, ABS, brake related ADAS components, modern brake pads, and more.

8 Study Hours

- Development of brake systems from past to present.

- Types of brake pad materials.

- Proper use of tools and techniques for modern and legacy brake system service.

- Hybrid brake system components.

- Brake service issues with hybrid and electric vehicles.

INTERACTIVE

MODERN LIGHTING WORKSHOP

In this hands on workshop, students gain an understanding of the importance of properly adjusting, diagnosing, and abiding by regulations put in place for modern lighting systems used in cars on the road today.

This course covers basic topics such as, Lumen ratings and Kelvin temperatures, to advanced lighting topics such as, FMVSS108 standards and adaptive lighting techniques.

Topics include:

Lumen Ratings, kelvin temperatures, FMVSS108, and more.

8 Study Hours

- Define the difference between candela, lumens, lux, and kelvin temperature

- Measure light output with a Lux meter

- Determine the difference between HID, LED, laser, and halogen lights

- Recognize the difference between projector and reflector lights

- Identify all the different adaptive lighting features

INTERACTIVE

COOLING SYSTEMS AND COOLANTS WORKSHOP

In this hands on workshop,The students will covers basic cooling systems features and functionality.

Topics discussed will include how thermostats, water pumps, radiator caps, and more operate. You will also get insight into quick and effective diagnostics of cooling system components along with the proper tools needed to complete the job right the first time. Also, you will learn about different types of coolant and what advantages each style provides.

Topics include:

theromstats,water pumps, radiator caps, cooling system components and more.

8 Study Hours

- Understand how cooling system components operate together to allow for increased engine performance and efficiency.

- Learn about different types of coolant and the pros and cons associated with each.

- Learn about the tools needed to quickly and efficiently diagnose faulty cooling systems.

- Identify safety concerns when working with cooling systems.

INTERACTIVE

GASOLINE DIRECT INJECTION (GDI) WORKSHOP

In this hands on workshop, the students will covers an in depth look at high pressure fuel pumps and direct unit injectors.

You will learn about the differences in troubleshooting these systems as compared to port fuel injection systems. Also, gain an understanding about how GDI can optimize both increased power and fuel efficiency. You will also gain an understanding of the drawbacks and additional maintenance concerns associated with GDI, and how port injection is making its way back into the picture to solve some of these concerns.

Topics include:

fuel injection systems, port injections, maintenance, and more

8 Study Hours

- Understand the operation of high- pressure fuel injection pumps and injectors.

- Learn about the tools and safety concerns associated with GDI systems.

- Learn how to quickly and efficiently diagnose these systems.

- Understand the benefits of GDI systems and what they mean in terms of performance, fuel economy, and emissions.

INTERACTIVE

CUMMINS GENERATIONS 5.9L WORKSHOP

In this hands on workshop, the students will cover the differences of the 5.9 Cummins engine family throughout the years.

It will take a deep dive into topics like common failures, injection pumps, injectors, turbos, and what to look for when properly diagnosing a Cummins engine. Also topics like setting valve lash, and camshaft servicing will be covered. You will gain an understanding of the advantages of common rail technology and what it allows us to do with modern diesel engines.

Topics include:

valve lash, camshaft, rail technology, diesel engines, and more.

8 Study Hours

- Describe the operation of injection pumps and injectors.

- Define how a turbocharger operates and the differences in design throughout the years.

- Analyze symptoms of failing components on Cummins engines and how best to fix them.

- Determine the differences between common rail injection and mechanical injection systems.

- Learn about common failure points and how to prevent catastrophic failures.

- Perform testing on fuel systems and understand the importance of using the correct fuels.